The Importance of Safety Glasses for Welding

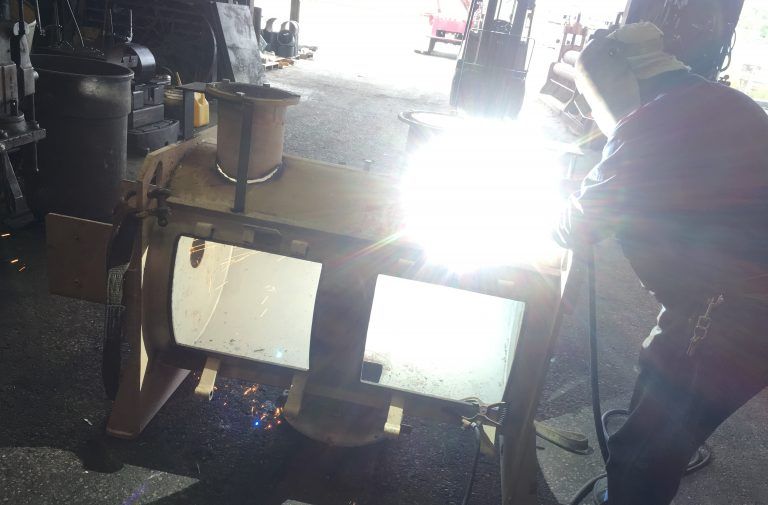

Eye injuries account for one-quarter of all welding injuries. This makes them by far the most common injury for welders, according to research from the Liberty Mutual Research Institute for Safety. Those most at risk for welding-related eye injuries are workers in industries that produce industrial and commercial machinery, computer equipment and fabricated metal products. Therefore, we will discuss the importance of safety glasses for welding.

Safety Glasses for Welding

Most workplace eye injuries occur due to small particles of objects (such as metal slivers, wood chips and dust) striking or abrading the eye, according to the National Institute for Occupational Safety and Health (NIOSH).

The U.S. Bureau of Labor Statistics (BLS) found that 70 percent of eye injuries studied came from flying or falling objects or sparks striking the eye. Injured workers stated that nearly three-fifths of the objects were smaller than a pinhead.

Welding Produces Harmful Invisible Rays

Welding produces visible light, which can be harmful, as well as invisible rays, including ultraviolet (UV) and infrared radiation (IR). While invisible radiation may be out of sight and therefore out of mind, it can cause damage without the worker immediately realizing it. Often times, the damage may not even become evident until years later. Generally, people experience exposure to radiation every day, from the sun, light bulbs, microwaves, etc.

However, welding poses a higher risk of health problems because of the intense concentration of light as well as the frequency of exposure because of the job. It’s not just welders who are risk either. In addition, employees who work in the general vicinity can also experience exposure to potentially damaging light.

Not Having Proper Protection Can Result in Health Problems

Photokeratitis

Various conditions can result if you don’t wear proper eye protection during welding. One of these conditions is a painful eye condition known as photokeratitis. It is also commonly known as snow blindness and arc eye. “Photokeratitis is like having a sunburned eye,” according to the American Academy of Ophthalmology (AAO). It affects the cornea, as well as the conjunctiva, which lines the inside of the eyelids and covers the white part of the eye. The damage from photokeratitis isn’t permanent, but it is extremely painful and irritating. Treatment typically includes avoiding bright lights for a length of time, which could mean not working temporarily. Symptom severity depends on the length of exposure. Symptoms include the following:

- sensitivity to bright light

- seeing halos

- pain

- blurry vision

- red eyes

- teary eyes

- headache

- swelling

- grittiness

- sensation of sand being in the eye

Cataracts

Workers also run the risk of getting cataracts if they don’t wear proper protection. Cataracts is when the lens of the eye, which is typically clear, becomes clouded. This can currently only be treated by having surgery. Symptoms include the following:

- cloudy vision

- frequent changes in eye-wear prescription

- double vision

- sensitivity to light

These are just a few reasons why safety glasses for welding are important. Brazos Industries follows all of OSHA requirements to ensure safety for everyone. Don’t hesitate to contact us with the link below for more information!

Many are unaware that drill bits require regular sharpening to give their best service. Similar to knives and axes, a dull drill bit requires much more force to do the same job. Instead of wearing the user out, a dull drill bit will inevitably wear out your drill. Giving your drill bits regular spot sharpening with a file is the best way to protect your investment in high-quality power tools. Brazos Industries knows the importance of properly sharpening drill bits, and we would like to share with you how to sharpen drill bits to protect your investment.

Following a regiment of appropriate and thorough maintenance procedures allows a welding machine to run safely and dependably for a long time. Improper, incomplete or totally neglected maintenance can not only result in equipment failure, but it can also lead to serious hazards including severe injury or even death. With some forethought and basic planning, welding machine maintenance is extremely easy.

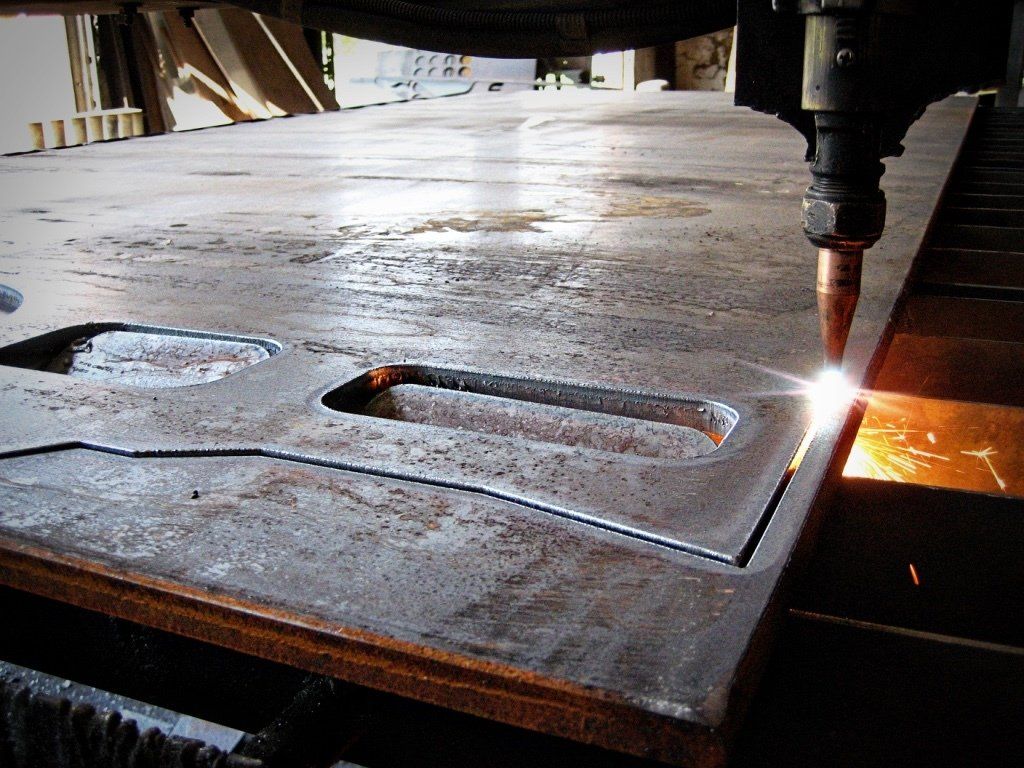

Air arc gouging is a process of removing metal by using heat generated from a carbon arc. This process utilizes a carbon/graphite electrode, compressed air and a standard power source. The extreme heat arc created between the electrode and a metal workpiece gouges and melts the workpiece. The compressed air also blows away the molten metal. This process is common for cutting stainless steel, carbon steel and alloys of copper, brass, aluminum and magnesium.

A good weld begins with good preparation, and good weld preparation begins with a clean cut. However, cutting is an art that requires both skill and knowledge of how to select and utilize the best grinding wheel for the job. The type of grinding wheel to use for a given application depends largely on what material you are cutting. We will discuss using the right grinding wheel for the welding job.

You can fit oxy-fuel torches with a “Cutting Head” and use them to cut one solid piece of metal into two or more pieces. Lighting, adjusting and shutting down an oxygen-acetylene torch is easy, particularly when following to proper procedures. We will discuss properly adjusting the flames for the oxy-fuel cutting.

Selecting the right cutting or styling tool for the job means the difference between an average cut or a great cut. Therefore, it is important to choose carefully. It is critical to both performance and safety to choose the correct tip for the job. Here’s a simple step-by-step process for choosing the right cutting tip to ensure you deliver a great cut every time.