Technology Advancements for Metal Fabrication: CNC Plate Burning

CNC plasma cutting has come a long way since paper punch machines, which were common to write G-codes for the cutting controller. We will discuss technology advancements for metal fabrication, specifically with press brakes.

Technology Advancements for Metal Fabrication

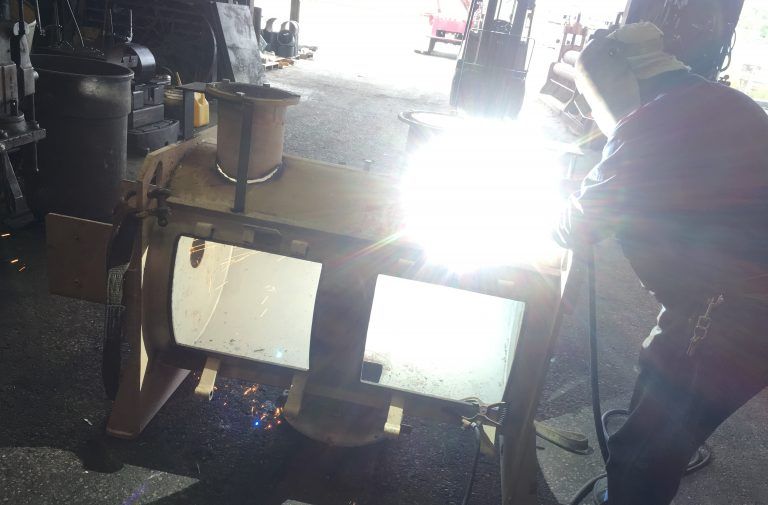

Not that long ago plasma cutting was the domain of seasoned metal fabrication veterans. They knew just how to tweak gas settings and adjust torch height to get the best cut on a plasma cutting table. Many of the highly trained technicians today have left the shop floor.

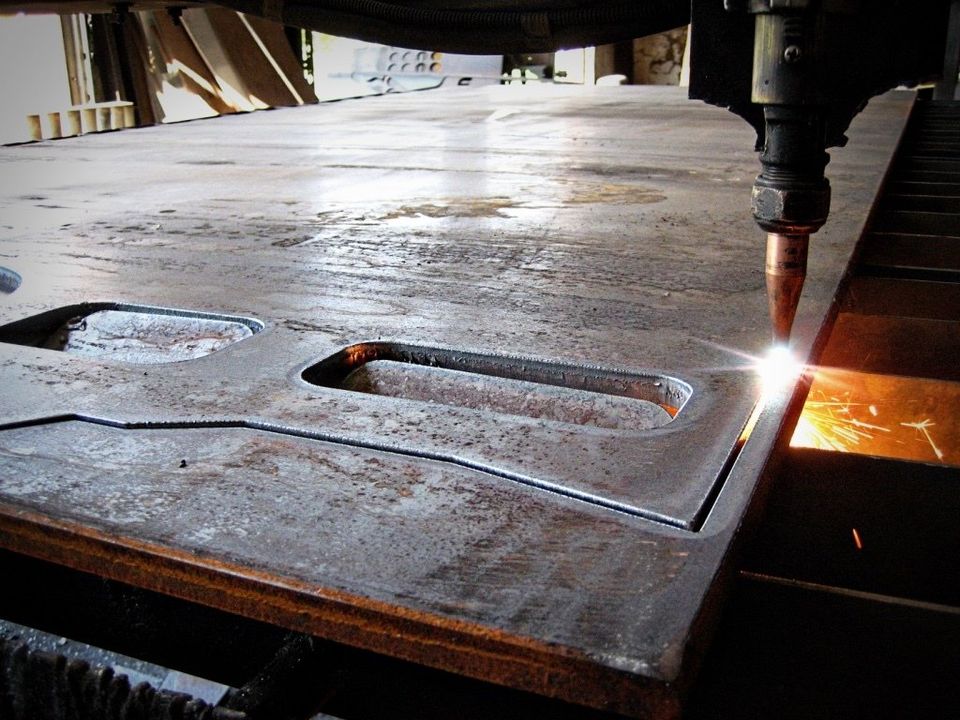

Today, the plasma cutting system still provides a quality cut but without the expertise needed to guide the machine. For many fabricators, this type of plasma cutting is the only type of plasma cutting they utilize. Technology advancements have helped to automate programming for plasma cutting systems, and highly precise plasma cutting is now a reality.

History of Plate Burning Technology

Th invention of the first plasma cutting and plate burning technology was in the mid-1950s.

At that time, the predominant method of thermal cutting was oxyacetylene cutting. An operator had to control the torch head by hand following a template. However, the operator could also mount the torch head to a gantry-style trace-eye machine or a linear tracking rail.

NC Gantry Machines

NC gantry machines became popular by the mid-1960s. The flame cutting process was revolutionized by the marriage of oxyacetylene to the NC gantry machines.

Plasma torches were available on the NC gantry machines. Paper punch machines were common to write G-codes to the controller.

Plasma Cutting

Manufacturers and fabricators didn’t typically accept plasma cutting until the mid-1970s in the U.S. A few reasons for the delay in the popularity of plasma cutting include the following:

- system costs, particularly the price of the gases required

- technology’s inability to match the thickness levels that oxyacetylene could cut

- lack of public knowledge about plasma cutting capabilities

- lack of programming expertise

Plasma cutting grew in popularity in the 1980s, as there was more manufacturing of low-amperage systems. As a result, thinner metals could be cut with plasma. This was also the introduction of electronic torch height control. Electronic controlling was necessary for the torch-to-workpiece distance. Therefore, the torch head could pierce the material at a greater distance from the workplace. This minimized consumable wear and contributed to a more precise cut.

PC for Equipment Programmers

During this period, the PC also gained popularity. Equipment programmers use the PC to generate machine G-code or ASCII text files. These were common to direct the machine controller. Many machines continue to utilize this technology today.

In the 1990s, high-precision plasma cutting became available. The edge quality a laser machine could produce was necessary for many cutting applications, but not the precise accuracy. These high-precision plasma cutting machines became an affordable option for these types of applications.

Plate Burning Technology Today

The refinement of high precision plasma technology, the advancement of electronic torch height control systems and the evolution of computer control technology have resulted in a popular contour cutting solution. Machine motion has improved as a result of advancements made in linear guiding, servomotors and gearing, including the following:

Linear guiding technology now features higher load capacities. Therefore, this allows for the mounting of a stronger guide system in a smaller place.

Tuning of sinusoidal AC servomotors takes place digitally, resulting in smoother motion and higher speeds.

Anti-backlash gear heads provide a rotary-to-linear motion which is more precise to achieve higher accuracy and torque.

Plasma cutting machines that feature these technologies have machine motion positioning accuracy of 0.004 inch. Without sinusoidal AC servomotors, anti-backlash gear heads and precision linear guides, systems of the past would achieve only 0.015-in. positioning accuracy.

The tighter tolerance as related to positioning accuracy minimizes corner overshoot and maintains straighter lines during diagonal moves. The higher accuracy in machine motion directly corresponds to higher part accuracy.

This has enabled plasma machines to produce parts similar to laser-cut parts. However, it is with less accuracy. For instance, 10-gauge cold-rolled steel sheet that’s laser-cut usually yields a part with an accuracy of ±0.005 inches. However, the same material cut with a high-precision plasma torch yields a part within ±0.012 inches. With this said, plasma cutting systems can cut thicker materials faster than lasers and produce quality parts at the same.

The Future of Plate Burning Technology

Important factors to keep in mind for fabricators considering a contour-cutting machine include the following:

edge quality and part accuracy needed

maintenance and operating costs

simplicity of use

Machine Programming Methods

A fabricator who has interest in newer plasma cutting technology needs to also focus on the machine’s programming methods. A new plasma cutting system has the ability to program parts with complex geometries, import DXF files from other CAD systems or accept G-code programs.

Automatic nesting of the part geometry, as well as the ability to change the nested part geometry by allowing the operator to drag the part around the sheet displayed on the computer screen should also be provided by the system’s software package. Lastly, the software system needs to keep track of jobs—what has and hasn’t been cut at the machine.

Skills and Aptitude New Technology

With technology advancements, the need for a new generation of experts in the metal fabrication industry increases as well. Metal fabricators today need to have skills in the trade. In addition, they need aptitude for the following:

- advanced fabricating processes

- computers

- other forms of technology

Future metal fabricators need to be familiar with plasma and laser fabrication technologies, as they will figure prominently in the future of the trade.

Over the years, we have expanded and continue to add capabilities of new machinery to satisfy growing customer needs. We carry a wide array of steel products for any of your current or future project needs. Contact us with the link below to purchase any of our products in inventory!

Many are unaware that drill bits require regular sharpening to give their best service. Similar to knives and axes, a dull drill bit requires much more force to do the same job. Instead of wearing the user out, a dull drill bit will inevitably wear out your drill. Giving your drill bits regular spot sharpening with a file is the best way to protect your investment in high-quality power tools. Brazos Industries knows the importance of properly sharpening drill bits, and we would like to share with you how to sharpen drill bits to protect your investment.

Eye injuries account for one-quarter of all welding injuries. This makes them by far the most common injury for welders, according to research from the Liberty Mutual Research Institute for Safety. Those most at risk for welding-related eye injuries are workers in industries that produce industrial and commercial machinery, computer equipment and fabricated metal products. Therefore, we will discuss the importance of safety glasses for welding.

Following a regiment of appropriate and thorough maintenance procedures allows a welding machine to run safely and dependably for a long time. Improper, incomplete or totally neglected maintenance can not only result in equipment failure, but it can also lead to serious hazards including severe injury or even death. With some forethought and basic planning, welding machine maintenance is extremely easy.

Air arc gouging is a process of removing metal by using heat generated from a carbon arc. This process utilizes a carbon/graphite electrode, compressed air and a standard power source. The extreme heat arc created between the electrode and a metal workpiece gouges and melts the workpiece. The compressed air also blows away the molten metal. This process is common for cutting stainless steel, carbon steel and alloys of copper, brass, aluminum and magnesium.

A good weld begins with good preparation, and good weld preparation begins with a clean cut. However, cutting is an art that requires both skill and knowledge of how to select and utilize the best grinding wheel for the job. The type of grinding wheel to use for a given application depends largely on what material you are cutting. We will discuss using the right grinding wheel for the welding job.

You can fit oxy-fuel torches with a “Cutting Head” and use them to cut one solid piece of metal into two or more pieces. Lighting, adjusting and shutting down an oxygen-acetylene torch is easy, particularly when following to proper procedures. We will discuss properly adjusting the flames for the oxy-fuel cutting.

Selecting the right cutting or styling tool for the job means the difference between an average cut or a great cut. Therefore, it is important to choose carefully. It is critical to both performance and safety to choose the correct tip for the job. Here’s a simple step-by-step process for choosing the right cutting tip to ensure you deliver a great cut every time.